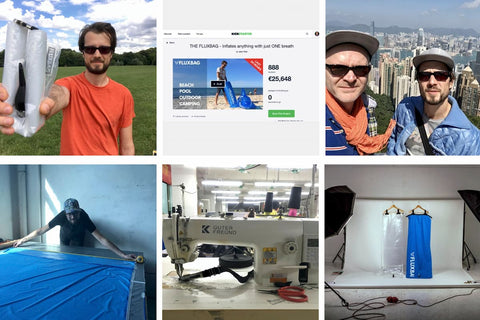

In June 2016 I come up with the idea that would soon become the FLUXBAG. With my best friends Lucas, we make the first prototypes from PE tube foil – and the thing really works. We buy fabric, improvise some nozzles and connectors – and it works even better! Has no one ever before thought of a modular or XXL pump sack, we ask ourselves? Nope, in turns out. We’re actually first.

We launch a Kickstarter campaign in August and fail to generate enough momentum. We abort, relaunch a few weeks later and raise 25K EUR from 888 backers. In November, we go to China to meet our first manufacturer in Dongguan. The first 1,700 FLUXBAGs are being made. We ship them directly from Hong Kong to 50 countries across the world.

In March 2017 we are filming for “Die Höhle der Löwen” – the official German version of “Shark Tank”. We are very tense and our performance isn’t particularly good. Regardless, “Shark” Ralf Dümmel signs up for the FLUXBAG.

Endless trickeries, negotiations and delays enfold over the next months before we finally can sign a contract to license the product to Ralf’s company. They have it made by their own suppliers – while we’re traveling to China again to work with a new, larger manufacturer ourselves, and make our own FLUXBAGs with much better fabrics.

The TV show airs in September 2017; about three million people in Germany are watching. The whole thing is a huge disappointment. We’re selling no more than a couple of hundred units online. At the same time, Ralf’s team has put the product out in retail all over Germany – BIG time. Wherever you go, there are FLUXBAGs on the shelves. This guy knows his business! We think...

When the first license statement from our “TV shark” comes in, it becomes clear, however, that their product largely bombed. Although the retail purchase managers were utterly ecstatic and ordered tens of thousands of units, the product did not sell in general retail. They priced it too high, the packaging was just ghastly, and people just could not understand how to do handle the product. Little wonder, when the suffocation safety warnings are least twice as extensive as the how-to-flux instructions. – Ralf’s company has huge overstock. Their fault - our problem.

As spring arrives, our own Amazon sales in Germany and the US are picking up though. I make the product a true Amazon.de bestseller after all. Nevertheless, we have way too much money tied up in stock. Liquidity becomes ever tighter as the company needs to pay its taxes. I am burning out. This ain’t fun anymore.

Over the later months of 2018, sales on Amazon had dried up. People realised that our whole set of plastic parts was not really up to it: Nozzles pop off and you need super-human powers to disassemble parts. Connections with Boston and other kinds of valves are missing. The textile bodies are brilliant but everything plastic we made, it turns out, is rather crappy.

I discuss the situation with Lucas who is in charge of the product and supply chain but he is too frustrated and not prepared to work on a solution. We break up. Having been best friends for long years and having started this together, this is the saddest thing.

Burned out but not prepared to give up yet, I make an attempt to turn things around. In spring 2019 I launch a new Kickstarter campaign that shall provide the funds to make a new set of nozzles and adapters that actually works. A few weeks later, the company is going into administration and the new Kickstarter money is lost. I feel like a complete failure and fraud. The best thing I achieve over the next year is not to kill myself.

With the help of Dennis, I re-re-design all the plastic parts to perfection. Having overstock textile FLUXBAG bodies parked in China, now becomes a blessing: With just about feasible new investment, I am able to revamp the product completely. I’m bootstrapping again but I do love it – again.

Now, with the new nozzles and adapters, the FLUXBAG finally is the product it was meant to be right from the start: A really smart air pump – and surely the world’s best pump bag.